Table of Contents

- Introduction

- Environmental Benefits of Metal Recycling

- Technological Advancements in Recycling Facilities

- Economic Impact on Local Communities

- Case Study: Aurubis’ U.S. Copper Recycling Plant

- Challenges and Regulatory Developments

- The Future of Metal Recycling

Introduction

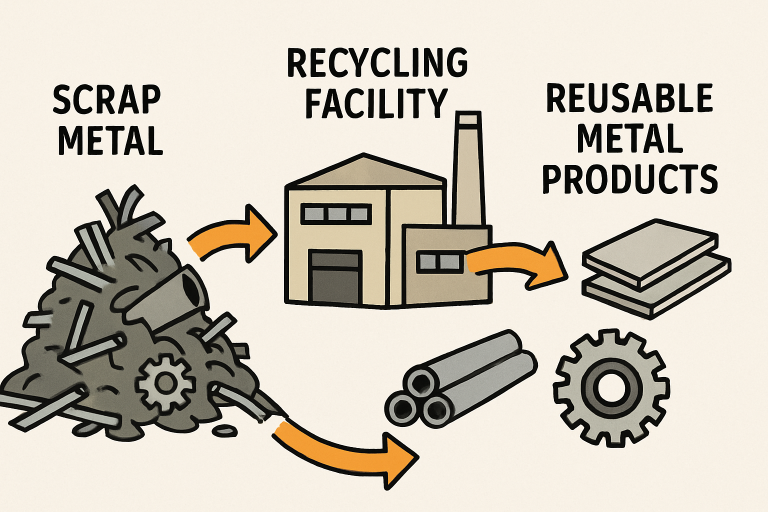

Millions of tons of scrap metal are generated annually from industrial waste, discarded household items, and obsolete electronics. Instead of allowing these valuable materials to fill landfills, metal recycling facilities have emerged as a crucial link in the sustainability chain, transforming discarded scrap into useful raw materials. Suppose you’ve ever wondered what can metal be used for beyond its initial purpose. In that case, the answer is nearly limitless—recycled metals are foundational to construction, manufacturing, and green technologies like electric vehicles and wind turbines.

Modern recycling plants address waste management issues, conserve significant natural resources, and reduce overall environmental impact. By focusing on efficient, scalable recycling processes, these facilities are not just keeping scrap out of landfills—they are powering the circular economy, fostering innovation, and supporting local jobs. The impact reaches beyond the facility gates, resonating through communities, economies, and ecosystems worldwide.

Environmental Benefits of Metal Recycling

Recycling metals is one of the most effective ways to conserve nonrenewable resources and minimize human activities’ environmental footprint. According to the U.S. Environmental Protection Agency (EPA), recycling aluminum, steel, copper, and other metals drastically reduces the need for raw material extraction. For example, recycling aluminum saves up to 95% of the energy required compared to extracting aluminum from bauxite ore.

These dramatic energy savings have cascading environmental benefits. Lower energy consumption results in a notable reduction of greenhouse gas emissions, helping to mitigate climate change. Additionally, recycling metals like steel and copper relieves pressure on natural environments otherwise disturbed by mining operations, preserving biodiversity and reducing the risk of hazardous runoff that can contaminate water supplies.

Technological Advancements in Recycling Facilities

Innovative technology is reshaping the scrap metal recycling industry, making the process faster, more effective, and capable of handling increasingly complex waste streams. Artificial intelligence (AI)- powered sorting systems and precision robotics can identify, sort, and separate metals within mixed-material waste at unparalleled speeds. Advanced analytical tools—like X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS)—can determine exact chemical compositions, ensuring optimal purity in recycled materials and minimizing contamination.

These advances not only increase the quality of recycled metal but also lower the overall cost of production, making sustainable materials more competitive with newly mined ores. With real-time data and more innovative logistics, recycling facilities can maximize efficiency and minimize waste, reinforcing the industry’s role at the heart of a greener future. The industry’s adoption of these innovations underscores how circular economy strategies increasingly rely on high-tech solutions.

Economic Impact on Local Communities

Besides the clear environmental gains, metal recycling facilities deliver substantial socio-economic benefits. The value chain—from collection and transportation to sorting, reprocessing, and distribution—requires a vast and skilled workforce, creating thousands of stable jobs. Local economies gain traction from these operations as small businesses and manufacturing sectors secure affordable access to high-quality, recycled raw materials.

Recycling facilities also alleviate the financial strain on local governments’ waste management budgets by keeping significant amounts of metal out of municipal landfills. According to a New York Times report, strong recycling programs enable cities to redirect resources toward community development, infrastructure, and other critical services, exemplifying the multiple layers of value generated by this industry.

Case Study: Aurubis’ U.S. Copper Recycling Plant

One of the most ambitious metal recycling initiatives in recent years is the $800 million copper recycling plant opened by Aurubis AG in Richmond, Georgia. Launched in September 2025, this facility can handle up to 180,000 metric tons of complex scrap annually, turning discarded circuit boards, copper wires, and industrial byproducts into 70,000 tons of sustainable blister copper. Aurubis’ investment is a prime example of how large-scale recycling efforts can strengthen national supply chains, lessen dependency on imported metals, and inspire similar projects throughout North America and beyond. Read more about Aurubis’ Richmond plant.

Challenges and Regulatory Developments

Despite continual advancements, metal recycling companies must navigate an evolving landscape of regulatory and operational hurdles. Some states are moving to centralize regulatory oversight for recyclers, as highlighted by California’s Senate Bill 404, which proposes bringing recyclers under the purview of statewide agencies. Supporters argue that such reforms would improve transparency and consistency, but some environmental groups warn of potentially diluted local protections and diminished scrutiny of facility practices.

The challenge for policymakers and industry leaders remains balancing streamlined regulatory processes with stringent safeguards to protect communities and the environment. This balance is essential for long-term industry viability and public trust. Ongoing dialogue and adaptive policy reforms will help chart a sustainable path forward for all stakeholders involved in metal recycling.

The Future of Metal Recycling

The outlook for metal recycling is bright, with emerging trends poised to redefine global waste management and resource extraction. Urban mining—recovering valuable metals from e-waste like smartphones and computers—is gaining momentum as cities seek innovative ways to manage surging volumes of obsolete electronics. Further integration of AI, robotics, and real-time data analytics will streamline recycling even as waste streams diversify and grow more complex.

As governments, manufacturers, and consumers increasingly prioritize climate action and circular economy principles, metal recycling will remain a cornerstone of sustainable industry. Facilities equipped to adapt quickly to regulatory change, leverage technology, and engage local communities are set to drive the next wave of economic and environmental progress worldwide.