Introduction to Advanced CNC Techniques

Computer Numerical Control (CNC) machining is the foundation of modern manufacturing, enabling highly accurate and efficient production of intricate parts across industries. As manufacturing challenges evolve, manufacturers are turning to advanced CNC techniques to handle tighter tolerances, more complex geometries, and ever-increasing demands for consistency and quality. Companies like Phantom CNC Systems are playing a key role in bringing these advanced capabilities to modern shops, offering solutions that meet the requirements of precision-driven sectors.

The evolution of CNC has not only enabled higher accuracy but also expanded what is possible in product design and manufacturing workflows. This shift is crucial for keeping pace with industry leaders and responding to growing market expectations. By adopting innovative CNC methods, manufacturers can achieve significant improvements in both speed and performance, influencing everything from prototyping to full-scale production.

With ongoing innovation, the field of CNC machining is becoming more diverse. Innovations such as multi-axis machining, integration with artificial intelligence, and the blending of additive and subtractive techniques are reshaping factories worldwide. Whether you are in aerospace, automotive, or medical device manufacturing, staying abreast of CNC advancements is essential to remain competitive.

Multi-Axis Machining: Enhancing Complexity and Precision

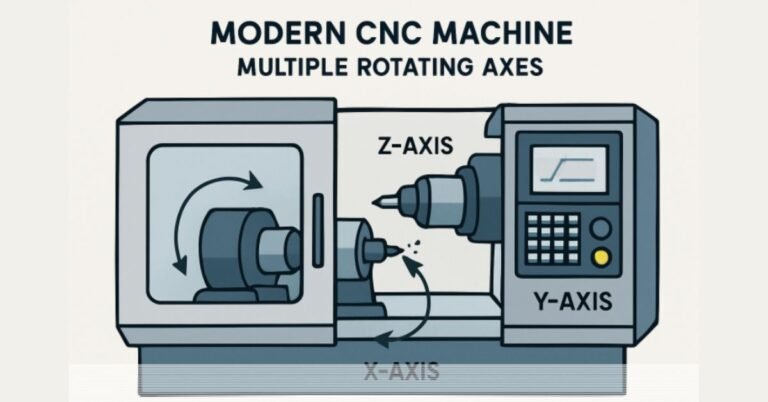

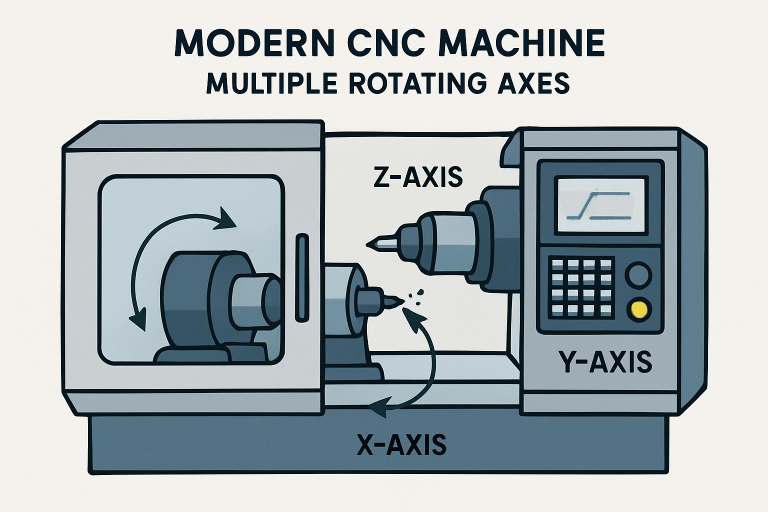

Standard CNC milling machines operate along three linear axes (X, Y, and Z), which limits their ability to create workpieces with undercuts, deep cavities, or complex contours without part repositioning. Multi-axis machining introduces additional axes of rotation, typically allowing machines to operate on four, five, or even more axes simultaneously. This expands manufacturing options, enabling the production of highly detailed parts in a single setup and minimizing errors introduced by manual repositioning.

Multi-axis CNC machines have enabled the fabrication of components such as turbine blades, medical implants, and intricate automotive parts with unparalleled precision. By significantly reducing fixture complexity and setup time, these systems not only increase throughput but also reduce costs. Industries that demand perfection, such as aerospace, widely use multi-axis machining to ensure the quality of mission-critical components.

Benefits and Challenges

While the benefits are significant, multi-axis CNC setups can require specialized programming knowledge and a higher initial investment. However, the return on investment can be substantial thanks to reduced cycle times and enhanced flexibility in part design.

Integration of AI and Machine Learning in CNC

Artificial Intelligence (AI) and Machine Learning (ML) are transforming how CNC machines are programmed, monitored, and maintained. By processing large datasets, these technologies can optimize tool paths, predict tool wear, and identify potential quality issues before they result in defects. For example, AI-driven predictive maintenance schedules help minimize unplanned downtime, saving both time and resources.

Machine learning algorithms continually analyze operational data from sensors and controllers, allowing for real-time adjustments to machining parameters. This leads to improved production consistency and helps manufacturers meet the stringent demands of sectors such as electronics, automotive, and aerospace. According to a recent Forbes article, companies embracing AI in manufacturing are reporting reduced defects, greater product throughput, and higher customer satisfaction.

High-Speed Machining: Accelerating Production

High-Speed Machining (HSM) pushes the boundaries of how quickly and efficiently materials can be shaped without sacrificing quality. This technique leverages advanced tooling, spindle speeds, and toolpaths designed to minimize heat generation and vibration, thereby improving surface finish and dimensional accuracy. HSM is vital for industries where speed to market is a competitive differentiator, such as consumer electronics.

Adopting HSM enables manufacturers to significantly reduce machining times, especially for components made from aluminum and other soft materials. Additionally, it allows for less frequent tool changes and longer tool life due to reduced loading and smoother cutting.

Additive Manufacturing: Combining 3D Printing with CNC

The integration of additive manufacturing (3D printing) with traditional CNC machining yields a powerful hybrid approach that is revolutionizing the production of complex parts. Prototypes and near-net-shape parts can be quickly produced using 3D printing, then finished with CNC machining to achieve tight tolerances and fine surface finishes.

This combination not only shortens product development cycles but also supports the creation of intricate geometries that would be difficult or impossible to achieve using only subtractive methods. Industries ranging from aerospace to custom healthcare are capitalizing on hybrid manufacturing to innovate and accelerate time-to-market.

STEP-NC: A Modern Approach to CNC Programming

Traditional CNC programming using G-code is being challenged by STEP-NC, a next-generation programming standard. Unlike G-code, STEP-NC includes comprehensive manufacturing information, such as material specifications, features, and tolerances, in addition to geometric instructions. This enables a more integrated approach across the design and production process, minimizing communication errors and production delays.

Adopting STEP-NC not only streamlines workflow but also enhances flexibility and adaptability in a rapidly changing manufacturing landscape. This approach is helping manufacturers adapt to the increasing complexity of modern engineering projects.

Augmented Reality and Computer Vision in CNC Operations

Augmented Reality (AR) and Computer Vision technologies are enhancing CNC machining by providing interactive visual overlays and real-time analysis during setup, monitoring, and inspection tasks. Operators can see virtual guides and inspection criteria superimposed directly onto the workpiece, improving decision-making and reducing costly mistakes.

Systems that utilize these technologies streamline training for new workers, help catch errors before production starts, and integrate manual and digital workflows with unprecedented ease. By allowing quick access to vital process information, AR and computer vision further reduce error rates and improve overall manufacturing quality.

Final Thoughts

Advanced CNC techniques are transforming the manufacturing industry, empowering manufacturers to achieve greater accuracy, speed, and flexibility. By leveraging innovations such as multi-axis machining, artificial intelligence, high-speed techniques, hybrid manufacturing, modern programming standards, and real-time visualization technologies, the sector is preparing for a smarter, more efficient future. Embracing these methods not only improves product quality but also ensures continued competitiveness in a fast-evolving market.