Introduction

Material handling is the backbone of productive and cost-effective warehouse operations. By focusing on both safety and efficiency, you can greatly improve workflows and protect your team from unnecessary risks. One crucial element in this pursuit is investing in quality equipment—such as polyurethane wheels—to ensure smooth, safe movement of materials throughout your facility. Choosing the right wheels and casters reduces friction, wear, and injury risk, supporting a safer and more efficient work environment from the ground up.

Improving your material handling practices isn’t just about equipment; it’s also about optimizing processes, workspace design, staff training, and sustainability. By implementing the strategies outlined below, warehouses can achieve greater productivity while keeping employees safe and lowering operating costs.

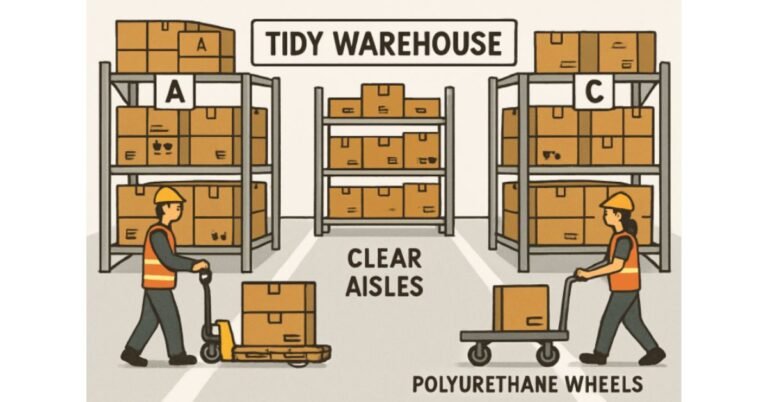

Optimize Warehouse Layout

An intelligently designed warehouse layout is fundamental for minimizing wasted movements and ensuring the safe, efficient transfer of goods. Consider taking advantage of your building’s vertical space with racking systems to maximize storage without increasing your footprint. Place high-rotation items closer to packing and shipping zones, which minimizes travel time and speeds order fulfillment. Keeping aisles wide and free of clutter not only makes it easier for workers and equipment to move quickly, but it also significantly reduces accident risks.

Implement Ergonomic Practices

Workplace injuries in material handling are often preventable with strong ergonomic measures. Train your team members on safe lifting techniques—such as lifting with the legs, maintaining a neutral spine, and keeping loads close to the body. Invest in lifting aids like hoists, conveyors, and height-adjustable tables, which drastically reduce the strain of manual handling. Design workstations that support natural movement, minimizing the need for repetitive reaching or awkward postures.

Leverage Automation and Technology

Automation is revolutionizing how materials flow through warehouses. Automated Guided Vehicles (AGVs) and conveyors can move items swiftly between storage and shipping, limiting reliance on manual labor and boosting safety by eliminating potential contact points. Integrating a robust Warehouse Management System (WMS) helps you optimize picking routes, track inventory in real time, and minimize errors. At the same time, barcode and RFID solutions enable seamless item tracking across the entire supply chain.

Conduct Regular Training and Safety Programs

Continuous education is a cornerstone of both safety and operational excellence. Routine training sessions ensure everyone is up to date on best practices for equipment operation and safe material handling. Perform regular safety audits to proactively address hazards such as blocked exits, equipment malfunctions, or improper storage. Make sure emergency plans—ranging from evacuation routes to first aid procedures—are communicated and regularly reviewed. This culture of safety helps prevent accidents and fosters employee confidence.

Standardize Processes and Procedures

Consistency in workflow not only improves efficiency but also maintains a safer workplace. Develop and implement clear Standard Operating Procedures (SOPs) for all key material handling operations. Adopt lean methodologies, such as the 5S system (Sort, Set in order, Shine, Standardize, Sustain), to keep workspaces clean, organized, and optimized for flow. Employees are often the best source of process improvement ideas, so regularly solicit feedback and involve them in refining procedures.

Prioritize Equipment Maintenance

Routine equipment maintenance prevents costly downtime, extends equipment life, and supports a safer environment. Schedule recurring inspections and servicing for all material handling tools—such as forklifts, pallet jacks, and conveyor systems. Address minor issues quickly before they escalate into major hazards or breakdowns. Maintain thorough records of maintenance and repairs for each piece of equipment to ensure compliance and accountability. Proper maintenance keeps your warehouse operating efficiently while minimizing injury risks.

Focus on Sustainability

Pursuing sustainability improves both your facility’s operational efficiency and its environmental impact. Opt for energy-efficient vehicles, lifts, and lighting to cut power usage and decrease emissions. Switch to recyclable and reusable packaging materials to significantly reduce waste output, and develop recycling and waste reduction programs for ongoing progress. Sustainable practices aren’t just good for the planet—they’re rapidly becoming an expectation for modern supply chains.

Monitor and Improve Continuously

Set clear performance metrics, like picking accuracy, order lead times, and equipment reliability, to pinpoint bottlenecks and measure progress. Conduct regular reviews and act on employee feedback to refine processes. Stay current with changes in material handling technology and safety standards to keep your warehouse competitive and compliant. Embracing a mindset of continuous improvement empowers your team and protects your bottom line.

Adopting these best practices for material handling creates a robust foundation for increased productivity, tighter cost control, and above all, a safer workplace for every employee—from new hires to seasoned professionals.