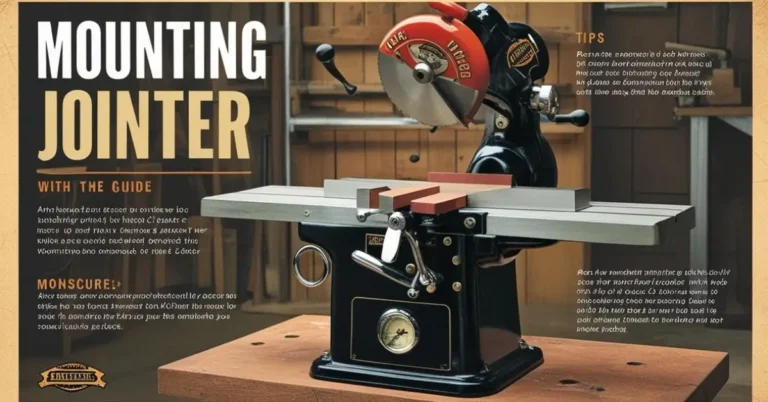

How to Mount a Vintage Jointer.Mounting a vintage jointer is an essential process for anyone looking to restore and use these classic tools. Proper mounting ensures the machine operates safely, efficiently, and with minimal vibration. In this guide, we’ll cover the entire process, from choosing the right base to securing the jointer, while also offering tips to maintain stability and longevity.

Why Mounting Matters

Vintage jointers are heavy, precision tools designed for creating smooth, flat surfaces on wood. Mounting them correctly not only guarantees their stability but also enhances their performance and safety. Poor mounting can lead to vibrations, inaccurate cuts, and even accidents. By following the steps in this guide, you can ensure your jointer is ready to serve you for years to come.

Preparing for the Job

Before diving into the process, gather the necessary tools and materials. These typically include:

- A sturdy base (metal stand, wooden bench, or mobile platform)

- Bolts and washers

- Rubber pads for vibration dampening

- Leveling tools

- Wrenches and screwdrivers

- Dust collection components (optional but recommended)

Also, inspect your jointer for any signs of wear or damage. Ensure all moving parts are in good condition and that the motor is functioning properly.

Choosing the Right Base

The first and most critical step is selecting a suitable base. The type of base you choose will depend on your jointer’s size, weight, and intended use.

Metal Stand

Metal stands are a popular choice for mounting vintage jointers. They are durable, capable of supporting heavy machinery, and often come pre-drilled for mounting specific models. Ensure the stand matches your jointer’s size and weight requirements.

Pros:

- Sturdy and long-lasting

- Minimal setup required

Cons:

- Typically lacks mobility

- May require additional vibration dampening

Wooden Bench

A wooden bench offers a customizable option for mounting your jointer. You can build one to your desired height and specifications, making it a great choice for those who enjoy DIY projects.

Pros:

- Fully customizable

- Can double as a workspace

Cons:

- Requires solid construction to support weight

- May transmit vibrations if not reinforced

Mobile Base

If you need flexibility in your workshop, a mobile base is an excellent option. These bases feature wheels or casters, allowing you to move the jointer easily. Look for models with locking mechanisms to keep the jointer stable during operation.

Pros:

- Easy to move and store

- Saves space in smaller workshops

Cons:

- Stability can be an issue during use

- Requires careful selection of weight capacity

Step-by-Step Mounting Process

Once you’ve selected a base, follow these steps to mount your vintage jointer:

1. Prepare the Base

- Metal Stand: If using a metal stand, check for any loose parts or irregularities. Ensure the stand’s surface is level and free of debris.

- Wooden Bench: Build a sturdy bench using high-quality wood. Reinforce the structure with cross-bracing to handle the jointer’s weight.

- Mobile Base: Assemble the base according to the manufacturer’s instructions. Ensure the casters are heavy-duty and have locking mechanisms.

2. Position the Jointer

Place the jointer on the base carefully. Due to its weight, you may need assistance. Align the jointer so that its base rests evenly on the stand or bench. Use a level to ensure the jointer is perfectly horizontal.

3. Secure the Jointer

- Use bolts and washers to attach the jointer to the base. Pre-drilled holes on metal stands or wooden benches make this process easier.

- Tighten the bolts securely but avoid overtightening, which could damage the jointer or base.

- To minimize vibrations, place rubber pads between the jointer and the base before bolting.

4. Mount the Motor

Most vintage jointers use an external motor. Proper motor placement is crucial for optimal performance.

- Position the motor so that the belt aligns perfectly with the jointer’s pulley system. This alignment ensures smooth operation.

- Use a hinged mounting surface if possible. The hinge allows the motor’s weight to maintain proper belt tension, reducing the need for manual adjustments.

- Double-check the belt tension and alignment before proceeding.

5. Install the Electrical Components

- Ensure the motor is wired correctly and safely. If you’re not comfortable with electrical work, consult a professional.

- Install a power switch in an easily accessible location, ensuring it’s far enough from the jointer’s moving parts.

6. Test for Stability

Before using the jointer, test its stability by pushing and pulling lightly on the machine. It should remain firmly in place without any wobbling or vibrations. If there are issues, adjust the bolts or base as needed.

7. Set Up Dust Collection (Optional)

To keep your workspace clean, integrate a dust collection system. Attach a dust port or chute to the jointer’s output area. Connect this to your shop vacuum or a dedicated dust collector.

Tips for Long-Term Use

Regular Maintenance

- Clean the jointer after each use to prevent buildup of dust and debris.

- Lubricate moving parts regularly to reduce wear.

- Check for loose bolts or connections periodically.

Knife Adjustments

Proper knife alignment is critical for achieving clean cuts. Adjust the knives so they are level with the outfeed table and evenly spaced in the cutterhead.

Safety Precautions

- Always use push blocks to guide wood through the jointer.

- Wear safety goggles and hearing protection.

- Avoid loose clothing or jewelry that could get caught in the machine.

Comparison of Mounting Options

| Mounting Option | Best For | Key Features | Potential Drawbacks |

|---|---|---|---|

| Metal Stand | Heavy-duty jointers | Sturdy, pre-drilled for mounting | Lacks mobility |

| Wooden Bench | Custom setups | Customizable, doubles as workspace | Requires solid construction |

| Mobile Base | Small workshops, flexibility | Easy to move, space-saving | Stability can be a concern |

Conclusion

Mounting a vintage jointer is a rewarding process that ensures the tool remains safe and functional for years to come. By selecting the right base, securing the machine properly, and maintaining it regularly, you can enjoy the benefits of this timeless woodworking tool. Whether you’re a hobbyist or a professional, taking the time to mount your jointer correctly will pay off in improved performance and safety.

For a detailed visual guide, search for videos online to complement this written tutorial. These resources often provide step-by-step demonstrations that can help clarify the process further.